News » We now reveal the secret of using a GPS row guide correctly!08 May 2018 11:16

Assistance for users of row guide devices

If a work is inaccurate, most frequently the row guide is the device to take the blame, even though the user is at fault in the majority of cases. This can most often be traced back to an unrealistic view of users as to how row guide devices work.

In the following, we shall not consider physical disorders such as inadvertent disconnections, cable ruptures and bent pins of connectors resulting from inaccurate connections, etc. We will now focus on a single problem: “My row guide is inaccurate.”

In the following, we will use the most frequently occurring examples to demonstrate what factory may cause inaccuracy and what the available remedies are.

The row guide is inaccurate when used in a cultivation trace of a plant culture.

This is explained by the fact that the seeds were sown according to a track marker and not a row guide. Therefore, sowing was carried out parallel to the edge of the plot, and if this latter had any slight curvature, it may have resulted in significant deviations. The same phenomenon occurs e.g. upon a minimally small hill, where the curvature is not even spotted by the human eye, but the GPS detects it. As the row guide connects the A and B points placed at the two sides of the plot with a straight line, and it will never be identical to a row sown using a track marker.

Solution

- Use a high precision row guide device at sowing for preparing the cultivation tracks.

- If a cultivation track is available and trampling is to be avoided, spraying should be performed according to the cultivation track.

The device is accurate at the beginning of the plot and becomes increasingly less accurate as the other side of the plot is approached, and it is always accurate at a certain part of it.

This is most easily experienced upon spraying a maize plot sown with a row guide device. As the sowing had been performed using a row guide, the rows may be assumed to be straight. Still, upon spraying, inaccuracy is linearly increasing, e.g. when approaching the end of the row.

Before we proceed, it is worth clarifying that while the row connection accuracy of a device is, depending on its type, around 15-30 cm, the accuracy of the absolute position with an LD-Agro EPS GPS receiver is 60 cm, and with GeoX1 and GeoX4 GPS receiver it may even be as much as 1-3 metres.

The explanation of the increasing inaccuracy is that it is possible that the device may have assumed point A to be exactly on the given maize row when recording it, but may have shifted by 1-3 metres, resulting from the technical parameters of the GPS receiver when assuming point B. After the row guide had connected points A and B, this line was no longer parallel to the maize rows, but was at an acute angle to it. Therefore, the row guide will keep exactly to the row on point A’s side, but when approaching the plot’s other side towards point B (since you will not drive off the row in order not to trample the maize), you will see increasingly greater numbers, indicating how far you are from the ideal row. This may even be as much as 1-3 metres at the end of the plot, at point B.

Solution

The 1.5 m inaccuracy upon assuming point B is caused by the fact that the tractor was stationary at that moment. For precisely determining points A and B, the tractor must be in motion, in order to have a direction vector and a velocity. For a stationary vehicle, the accuracy of a GPS receiver may be 1-3 metres without RTK correction.

Overlaps on the right and omissions on the left can be observed.

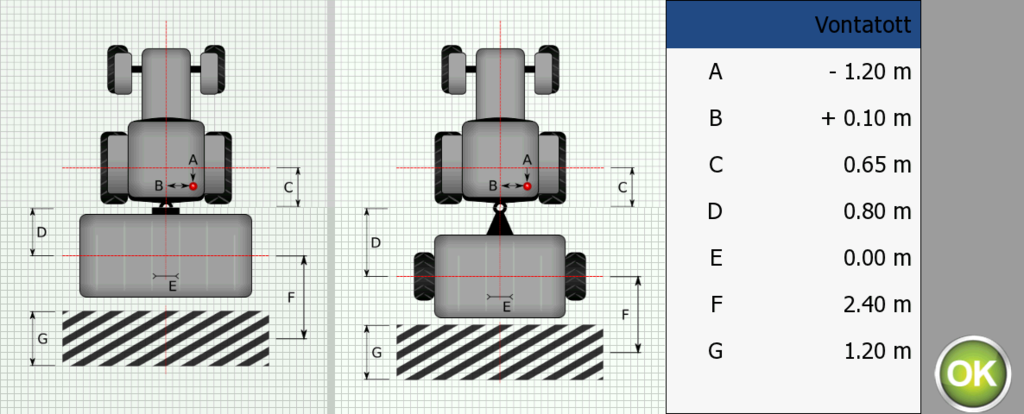

- Please check the offset of the GPS receiver in the settings, if it is switched on (according to the manual)!

- Please check in the settings if an asymmetrical machine had been set (according to the manual)!

- Please take a precise measurement of the width of the machine using a measuring tape. A machine whose working width does not change during its lifetime is close to being unprecedented. Measure precisely and adjust the actual working width’s correct values in the LD-Agro row guide.

- Please take a measurement of the width of the machine, right and left of the centerline of the tractor. It often happens that a 600 cm wide seed drill’s right side extends by a further 6 cm to the right. In this case, set an asymmetrical machine and correct the deviation (according to the manual)!

- Please check the condition of the machine and its fixation! Check if all wheels run free, or if there is an incorrect point of fixation causing the machine not to follow precisely in the tractor’s tracks. Repair the defect or set an asymmetrical machine in the settings to avoid the deviations!

There is an overlap on the zeroth line, in which the A-B straight line was taken.

This is part of normal operation, as work at the time of assuming points A – B is not yet done according to the row guide’s direction signals, and any surface irregularity or lateral movement in that row may result in significant overlaps upon turning around. It is recommended that the machine do not sow/spray/fertilise at the time of assuming the A-B points. After the A-B points have been taken, you may restart working even by following the reference line.

This is part of normal operation, as work at the time of assuming points A – B is not yet done according to the row guide’s direction signals, and any surface irregularity or lateral movement in that row may result in significant overlaps upon turning around. It is recommended that the machine do not sow/spray/fertilise at the time of assuming the A-B points. After the A-B points have been taken, you may restart working even by following the reference line.

An inaccuracy of 1-1.5 m is also present, I do not use the A-B straight line, as my plots are curved, I only turn next to the green band.

This is not proper usage, as this effectively deactivates the row guidance functionality, there is no control. If you attempt to turn on the green line according to the display, think of the following: the two centimetre band you see on the display panel may actually represent an 18 m wide machine. Therefore, should you only drive with a visual inaccuracy of 2 mm on the display panel, this would correspond to an actual deviation of 1.8 m in both directions.

Solution

Use the A-B straight line or the A+ curved row guidance function as described in the manual!

At times, the device functions well, while inaccuracies up to 1-1.5 m can be observed at other times.

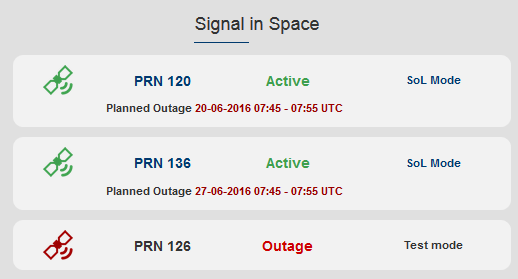

This phenomenon could be observed on Mg Navigátor V1 and V2 devices purchased before autumn 2016. (This phenomenon may no longer be present on devices purchased after autumn 2016.) The reason for this is found in the EGNOS correction satellite system, made up of 3 correction satellites. These 3 satellites are rather often not available, and sometimes they are under maintenance, and may periodically supply less accurate correction signals. This may also be the root cause of the problem, as it is quite possible that your device was set to a correction satellite, which may have terminated operation in the meantime or may only operate periodically.

This phenomenon could be observed on Mg Navigátor V1 and V2 devices purchased before autumn 2016. (This phenomenon may no longer be present on devices purchased after autumn 2016.) The reason for this is found in the EGNOS correction satellite system, made up of 3 correction satellites. These 3 satellites are rather often not available, and sometimes they are under maintenance, and may periodically supply less accurate correction signals. This may also be the root cause of the problem, as it is quite possible that your device was set to a correction satellite, which may have terminated operation in the meantime or may only operate periodically.

Information on the accessibility, quality and planned shut down of EGNOS satellites can be found on the website of the European Space Agency.

https://egnos-user-support.essp-sas.eu/new_egnos_ops/index.php

Solution

1. Inform yourself on the website of the European Space Agency on the availability of the EGNOS satellites!

2. If your device already supports the EGNOS switch on/off option, switch off reception of the EGNOS satellites if you observe inaccuracy!

3. Send your device to the nearest LD-Agro service centre, where reception of the EGNOS correction satellite will be deactivated in the device. Row guidance accuracy will only deteriorate by a few centimetres, but there will be no deviations of 1-1.5 m between rows.

In some plots the device functions well, in some others, it does not

This is roughly observed on one of every one hundred devices, and may especially interfere with the GPS signal processing of devices fitted with LD-Agro GeoX1 and GeoX4 GPS receivers. This phenomenon is not a defect of the GPS device, as it functions perfectly well in most cases, according to manufacturer’s specifications (e.g. in the service test area when sent back for servicing). Therefore, there may be some area specific disturbance factor behind the inaccuracy problem:

1. Airport with a radar station

2. Radio based industrial remote controlling, e.g. remote monitoring of a grain bin or gas tanks at agricultural cooperatives

3. High frequency transmission antenna

4. Hugh frequency transmission line (e.g. near power stations), which may interfere with GPS signals once in every hundred cases.

5. Hilly terrain with hills blocking out satellites

6. Work near a thick band of forest, where this may block out satellites

Solution

1. If your device already supports the EGNOS switch on/off option, first try to deactivate it, as these systems interfere with the frequency of the EGNOS satellite in most cases.

2. If your device does not yet have EGNOS switch on/off option, send the device to the nearest LD-Agro service centre, where reception of the EGNOS correction satellite will be deactivated in the device.

3. You need a more precise GPS receiver for your device, which is safe from being interfered by systems such as those listed above. In such cases, a solution can be the replacement off the GPS receiver, e.g. by an LD-Agro EPS GPS receiver. Consult your LD-Agro dealer on the available possibilities.

Finally, we describe the correct measurement procedure, used for the controls

1 Go to a free area - the best choice is a grassland or a football court. The measurement may be carried out both by a car or a tractor. Do not, by any means, check the accuracy of the GPS on a cultivation route!

2. Assume points A and B in the two ends of the plot while in motion! For simplicity’s sake, use a machine width of 10 m and never give a machine width of a few metres!

3. Proceed as instructed by the display panel!

4, Arrange for one person to assist you when you pass the middle of the plot and the row guide’s display panel also shows approximately the value of 0, and have this person place a marking peg at the towing eye of the tractor in every row! If you could not navigate precisely to 0 at the point in question, record the deviations for every row on a sheet of paper and add or subtract the corresponding value to the measurements later on! Use quarters for your notes here, e.g. west + 10 cm, as “left” and “right” are relative directions, changing with every turn! The further pegs placed must be in a single line and perpendicular to the direction of progress. Precise measurement takes place on the fly.

5, Measure the distances between the marking pegs! Please note: Never perform measurements between the first and second rows, as the first row is not navigated according to the GPS; only points A and B have been assumed there, nothing else! The reference line is not made of the track, but the straight line between points A and B. For checking purposes, public roads are the least suitable, as only a single return row can be completed, i.e. only a single row, on which the machine would travel according to the row guide’s instructions, and it cannot be measured against anything else.

More information on Row guides, row guidance GPS, agricultural GPS and GPS row guides!

LD-Agro Technologies

wwww.ldagro.com

- Home

- News

- Dealer Locator

- Meet with us

- Previous exhibitions

- Download

- About LD-Agro

- Contact

- Privacy policy

- Privacy statement

© 2024 LD-Agro Technologies Ltd. - All rights reserved. - ,,Professional GPS technology for agricultural use!“

Office

Office