Products » GPS Guidance System Displays

LD-Agro i840 ISOBUS Terminal

Product details

- 190 manufacturers to control power machines with ISOBUS

- 190 manufacturers to control power machines with ISOBUS

- Easily controllable for any tractorist

- Ideal if you bought power machine with ISOBUS without terminal

- A single terminal for all power machines with ISOBUS

- A good choice if you think in power machines with ISOBUS

- Quicker refitting, no connection issues exist

- No need for calibration of the connected power machines

- More place and better visibility for merely the single terminal

|

|

The various tractors, working tools can be connected by a single 9-pole ISOBUS standard connector! |

Why is ISOBUS needed?

In a farm a machine park consisting of a number of power machines and machinery originating from various manufacturers is typical and this trammels the communication between them. Previously the manufacturers of the machinery offered several different possibilities for the data exchange between the terminals placed in the tractor’s cabin and the machinery, however these manufacturer specific solutions were not compatible with each other. Manufacturers had this also recognized already earlier, therefore was the no. ISO 11783 standard born which incorporated communication between the machinery and power machines into a uniform system so that also tools of diverse manufacturers can co-operate with each other. The continuously evolving standard includes 14 layers, more and more functions are developed into the newer and newer versions.

In a farm a machine park consisting of a number of power machines and machinery originating from various manufacturers is typical and this trammels the communication between them. Previously the manufacturers of the machinery offered several different possibilities for the data exchange between the terminals placed in the tractor’s cabin and the machinery, however these manufacturer specific solutions were not compatible with each other. Manufacturers had this also recognized already earlier, therefore was the no. ISO 11783 standard born which incorporated communication between the machinery and power machines into a uniform system so that also tools of diverse manufacturers can co-operate with each other. The continuously evolving standard includes 14 layers, more and more functions are developed into the newer and newer versions.

ISOBUS – Manufacturer independent communication between the machinery and tractor

A single ISOBUS terminal is enough on the tractor on which even more machinery can be connected. So there is no more need for the separate own terminals of the machinery connected to the tractor, sith a single ISOBUS terminal is able to handle all functions of the machinery via the so-called virtual or universal terminal (VT, UT).

This universal terminal will control the machinery exactly the same way as if its own monitor would be connected to it. When the instrument is coupled to the ISOBUS able tractor, its own user interface downloads from the controller (ECU) on the ISOBUS terminal on the tractor. These already contain data and parameters of the given instrument, so calibrations are not needed. Thus the machinery does not have a separate monitor but the terminal on the power machine will display and control it.

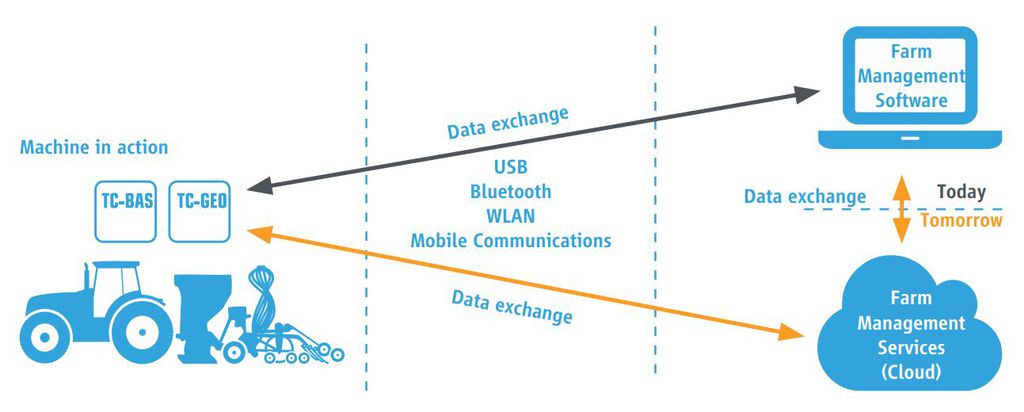

But the system knows even more, it standardizes the data exchange between the various work processes which is indispensable during the precision farming! It is able not only for line guiding, automatic sectionalization etc. but also facilitates the central collection and processing of data accruing during the use of various machinery. The different operations can be documented, so by means of an office software spreading plans can also be made, by which the proper amount can be locale specifically spread within a field for a higher yield – All these with optimum spreading!

Parts of the ISOBUS system

UT: The Universal Terminal (UT) provides the man-machine interface. This is the graphic display and central controlling system which is a touchscreen terminal. The operating software hosted in the controller of the machinery with ISOBUS will be loaded into the Universal Terminal. Therefore it is specifically important for the compatibility that you do not use a terminal with lover version number than UT Version3.

T-ECU: On tractors with ISOBUS a module, the Tractor electronic control unit (T-ECU) can be found. This reads e.g. the wheel sensor, speed, rpm, tractive force, tractor geometry, etc. data and transmits them to the machinery and the Universal Terminal.

Machinery-ECU: An electronic control unit (Machinery-ECU) can be found on every machinery with ISOBUS that contains the complete controlling software of the machinery. When connecting to a tractor with ISOBUS the Universal Terminal reads the controlling software from this.

AUX: By means of the (AUX) accessory on the UT terminal external elements can be joined to the system for the easier operation. E.g. Joystick, section switch, etc.

Task Controller: On the Universal Terminal is located the task controller (TC) program that has more parts and all of which serve different task. For the compatibility it is important to use a Task Controller with a version number as high as possible, minimum TC Version3 is recommended.

TC-BAS: Data logging with position and time, connection to the farm management software.

TC-GEO: Spreading map based quantity control

TC-SC: ISOBUS based automatic sectionalization of seeders, sprayers, fertilizer distributors. It allows the GPS based individual opening - closure up to 100 sections

Line guiding and auto-steering (TC-Guide, TC-Steer): If you do not have a line guiding device and your tractorists are highly trained, these two programs can be activated on the Universal Terminal. So you will have only one Universal Terminal for every machinery with ISOBUS, in addition for works requiring line guiding, auto-steering, too. From this point this will require a significant logistic organization from you. In case of a refittable UniDrive autopilot system also the Universal Terminal will be removed from the first tractor at the refitting, so for lack of the terminal the first tractor will not be able to operate any machinery with ISOBUS.

Therefore to control a machine with ISOBUS we recommend the LD-AGRO ISOBUS 840 terminal. And for line guiding, auto-steering we recommend a stand-alone system that provides a more operable and embraceable solution also for the tractorists!

Advantages of the device

ISOBUS terminal that supports every ISOBUS functionality. Its high intensity, 8.4” full glass surfaced screen that is well visible also in sunshine -can be operated by capacitive touch technology. The weather-resistant casing was designed for work, it operates in extended temperature range, moisture- and dust-proof. The integrated sensor system allows the use of brightness and color schemata oriented to the light conditions. The screen area can optimally be utilized by the function buttons and the near-by motion detector. During the use of the touchscreen additional buttons appear in a pop-up window which automatically resile at the end of use (ISOBUS Stop-All-Implement, ESC, ACK, HOME, App toggling). By means of the scroll-wheel the device remains accurately operable even in highly shaking environment.

Is the tractor without ISOBUS? – we retrofit in any tractor!

With the help of a so-called Retrofit ISOBUS set any tractors without ISOBUS can be converted to ISOBUS enabled tractor. Following the installation the machinery with ISOBUS and accessories will be already easily connectable! Parts of the system: LD-Agro T-ECU App, rear ISOBUS connector (Breakaway connector), inCAB connector, 6 m battery cable (15 and 40 amps), optionally GPS, GSM supplement.

With the help of a so-called Retrofit ISOBUS set any tractors without ISOBUS can be converted to ISOBUS enabled tractor. Following the installation the machinery with ISOBUS and accessories will be already easily connectable! Parts of the system: LD-Agro T-ECU App, rear ISOBUS connector (Breakaway connector), inCAB connector, 6 m battery cable (15 and 40 amps), optionally GPS, GSM supplement.

Type and machine independent

With the LD-Agro ISOBUS i840 terminal more thousands of machinery with ISOBUS of 190 manufacturers are operable.

- Home

- News

- Dealer Locator

- Meet with us

- Previous exhibitions

- Download

- About LD-Agro

- Contact

- Privacy policy

- Privacy statement

© 2024 LD-Agro Technologies Ltd. - All rights reserved. - ,,Professional GPS technology for agricultural use!“

Office

Office